The DIY revolution is coming to an industry near you. 3D printing – a technology that translates computer aided design, or CAD, files into tangible objects – is starting to have a significant impact on many industries’ operating models. The aerospace, oil and gas, manufacturing, and construction industries, to name a few, can leverage this technology to increase productivity and cut costs. Two enablers, understanding the context of this new tool and having a plan to embed 3D printing in an organization’s internal wiring, can ensure this new technology adds value in the long term.

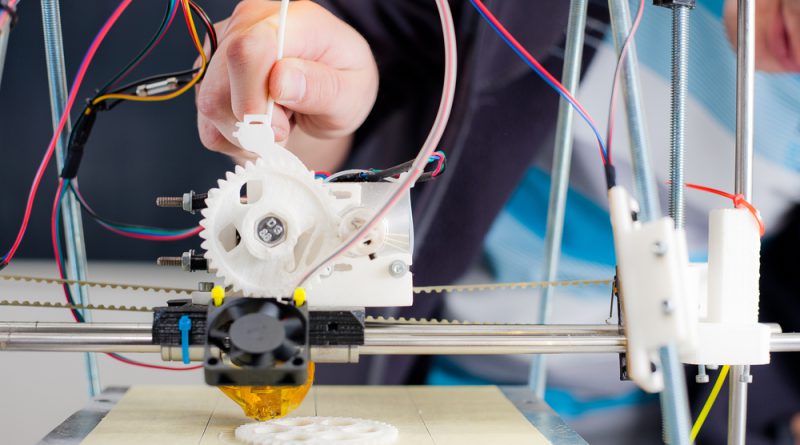

Conceptually, 3D printing is simple—just as printing a document in 2D is done by a printer head laying down tiny beads of liquid ink on a piece of paper per instructions sent by the computer, printing an object in 3D is done by a printer head laying down tiny beads of a plastic or metal in several layers per instructions sent by the computer. The file types and raw materials are different, but the idea that this technology can facilitate in-house production is the same.

The "so what":

- Construction project teams can quickly produce spare parts, reducing the critical path. The ability to print parts in-house can not only boost productivity, but also reduce waste and cut costs.

- Aerospace companies can use 3D printing to iterate new designs quickly and push new capital projects through faster.

- Oil and gas companies can build spare parts for upstream development projects that can prolong the life of capital intensive assets. (Oil & gas and metal refineries may also see a new revenue stream in providing the 3D printing market with raw materials.)

- Mine sites in remote areas can save significant time and money by 3D printing selected spare parts and components on-site.

The opportunity to add value from 3D printing comes at the heels of two critical enablers: First, the right external context that allows 3D printing to fundamentally alter operations; second, strong internal organizational wiring that forms the foundation for creating value sustainably.

First, the innovation ecosystem for 3D printing is evolving in different ways depending on the industry. The potential applications are easy to see, but fitting them into real-world operations is not simple. For example, construction companies may hit roadblocks from public works officials concerned about the safety of 3D printed bolts and beams. These roadblocks may require upskilling workers to meet regulatory requirements in building their own load-bearing parts, for example, which could pose a strong barrier in this industry as the new technology ramps up. Manufacturing companies, on the other hand, might benefit from 3D printing more immediately by making a working environment safer – avoiding putting people in dangerous situations to fix a spare part, for example.

The first step is to generate ideas about the possible applications of 3D printing in your business, and then rank them based on the value of implementing the new tech against the ease with which to integrate such tools into existing processes. Start simple with a wave of valuable ideas that are easy to implement. Indeed, careful consideration of context is fundamental to making the right choice of whether and when 3D printing is appropriate.

Second, 3D printing, like any digital solution, must be tightly linked to high-value performance improvement initiatives. Otherwise, you risk tossing a shiny new tool on top of an unstable or inefficient operating model. Bill Gates put it well when he said "The first rule of any technology used in a business is that automation applied to an efficient operation will magnify the efficiency. The second is that automation applied to an inefficient operation will magnify the inefficiency." Companies must consider the impact 3D printing will have on existing processes and organizational structure, as well as on employees to ensure that the system can support the new tool and that employees are properly incentivized and upskilled. 3D printing has the best chance to deliver sustainable value on the back of strong wiring.

PIP is helping clients understand the full picture of implementing specific digital solutions, such as 3D printing, by understanding the context as well as how the tool fits in to the overall performance improvement solution. PIP helps clients ruthlessly prioritize high-value ideas and ensure that digital tools are implemented in the right industry, at the right time, and in the right parts of the business.